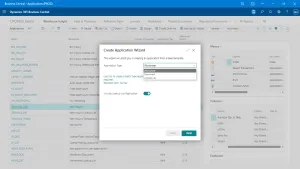

Features of Warehouse Insight

Inventory Management

Provides real-time updates on inventory levels and locations, helping warehouse managers make more informed decisions regarding stock control.

Barcode Scanning

Streamlines item receipt, picking, and inventory counts by using barcodes, reducing errors and improving operational efficiency.

Picking and Put-Away

Simplifies these essential warehouse tasks, enabling optimization of picking routes for speed and efficiency and defining put-away rules to maximize storage utilization.

Order Management

Facilitates handling sales and purchase orders, from the initial receipt of an order to the dispatch of goods.

Reporting and Analytics

Offers extensive reporting tools for performance tracking, identifying bottlenecks, and making data-driven improvements to operations.

Real-Time Data Syncing

Ensures all warehouse data is synchronized in real-time, providing accurate, up-to-date information to all system users.

Custom Workflow Capabilities

Allows for the creation of custom workflows to accommodate unique operational needs, improving process efficiency and productivity.

Receiving

Manages the receiving process to ensure accurate inventory.

Cross-Docking

Supports cross-docking operations to reduce storage requirements and speed up the delivery process.

Wave Planning

Enables batch order processing, or “wave planning,” for increased picking efficiency and better labor utilization.

Slotting Optimization

Uses historical data and AI algorithms to optimize the placement of items within the warehouse, reducing picking times and improving operational efficiency.

Advanced Shipping Notice (ASN)

Provides detailed information about incoming shipments, helping warehouses prepare in advance for receipt.

Lot and Serial Number Tracking

Ensures traceability of individual items or batches, crucial for quality control and recall situations.

Mobile Device Support

Facilitates use on mobile devices, allowing workers to access and update warehouse data on the go.

Multi-Warehouse Support

Allows inventory management across multiple warehouse locations, providing an integrated view of total inventory.

Automated Data Collection

Collects and analyzes warehouse data automatically, reducing the need for manual input and minimizing the risk of errors.

Bin Management

Assigns specific locations (bins) for each product in the warehouse, aiding quick and easy location of items.

Safety Stock Management

Helps maintain optimal safety stock levels to prevent stockouts without tying up too much capital in inventory.

Demand Forecasting

Uses historical data to predict future demand, enabling better inventory planning and reducing the risk of overstock or stockouts.

Kitting and Assembly

Supports the grouping of individual items into kits or the assembly of components into finished products within the warehouse.

Consolidated Pick, Pack, and Ship

Streamlines order fulfillment by enabling efficient picking, packing, and shipping operations.

Direct-to-Consumer Fulfillment

Manages the process of picking, packing, and shipping orders directly to consumers.

Product Information Management

Maintains detailed information about each product, including dimensions, weight, and other relevant details.

3PL Management

Supports collaboration with third-party logistics providers, ensuring smooth integration and communication for outsourcing warehousing or transport services.

Batch and Expiry Tracking

Manages products with expiry dates, such as food or pharmaceuticals, ensuring they are sold or used in time.